Little Treasury was fortunate to be invited to attend the Launch Event for the Bremont 2016 Limited Edition on June 29. As part of the planned activities we visited the case manufacturing facility in Silverstone, Northhamptonshire, headquarters in Henley on Thames, Oxfordshire, and a special side visit to Bremont partner. the Martin-Baker Aircraft Company in Higher Denham, Buckinghamshire. All three stops were eye openers, adding a depth of appreciation for this estimable watch company. The Silverstone facility is nestled in a light industrial park surrounded by specialty companies largely serving the car racing activities at the nearby Silverstone Formula I Circuit. We were greeted by Giles English, Co-Founder of Bremont, who hosted us throughout the facility tour. At Silverstone, Bremont has recruited technicians and machinists from the nearby automobile parts companies and retrained them for the more exacting standards of the watch manufacturing industry.

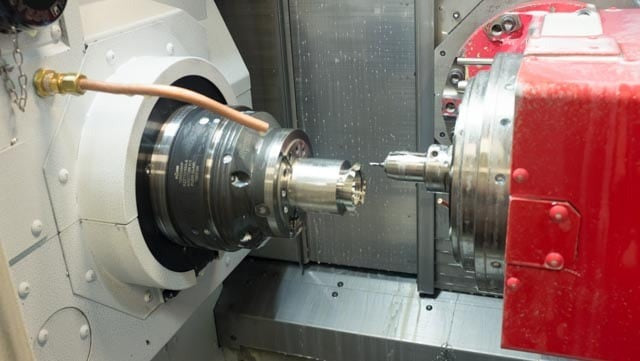

The Silverstone facility manufactures watch cases and movement base plates at present. The high-grade stainless steel rods are are cut into blanks that are individually machined into rough cases. The process is highly automated, with the operation running 24-7.

As automated as the process is, it still requires close supervision, as cutting and polishing materials change characteristics quickly and expert judgement is required to know when to switch out the old for the new.

Peter Mitchell, Engineer, explaining the case-making process.

Bremont owners can take satisfaction that their watch case is machined out of a solid block of material and not stamped. Stamping affects the integrity of steel and would limit the hardness that could be achieved as opposed to a machined case.

Once out of the automated polishing and drilling operation, the case is inspected and if passed it goes on to the polishing operation.

Polishing is labor-intensive. This technician told us that it takes three times as long to polish a polished-finish case against a standard matte finish, hence the premium for the highly polished ALT1-C/PW and ALT1-C/PB models as opposed to the matte ALT1-C's. Following inspection, cases that have passed are sent to an outside facility for the hardening process. I think we were all surprised how many steps it takes to produce a single case and how long even the automated steps take for each.

The Silverstone facility also produces base plates for some of the Bremont movements.

Also, laser engraving of case backs is conducted here.

It would not be Bremont if they could not fit in some atmospherics in the operation. Here we have the sail of an America's Cup catamaran that somehow found its way to Silverstone, and there was also a set of catamaran hydrofoils tucked away in a corner!